What materials are solar panels made of?

The materials used to make solar panel cells are only one component of the solar panel itself. Six different components are assembled during the solar panel manufacturing process to create a functional solar panel. Silicon solar cells, a metal frame, a glass sheet, standard 12V wire, and bus wire are among the components. If you are into DIY and are interested in solar panel materials, it may be as simple as wanting a hypothetical “ingredients” list to create one on your own. Here are the most common solar panel components explained:

Solar cells made of silicon

Metal framework (typically aluminum)

A sheet of glass

The glass casing sheet is typically 6-7 millimeters thick, and despite its thinness, it plays an important role in protecting the silicon solar cells within.

A standard solar panel includes, in addition to the solar cells themselves, a glass casing at the front of the panel to add durability and protection for the silicon PV. The panel has an insulation casing and a protective back sheet beneath the glass exterior, which helps to limit heat dissipation and humidity inside the panel. Insulation is especially important because temperature increases reduce efficiency, resulting in lower solar panel output. As a result, PV manufacturers must go to great lengths to ensure that light is captured without overheating the technology.

12V wire is standard

The bus wire

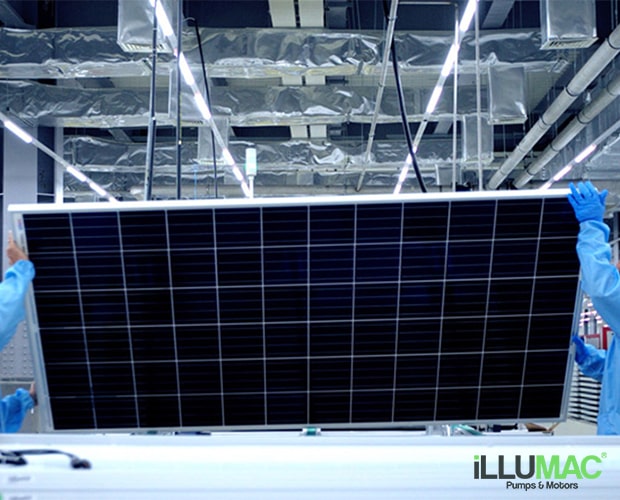

How are solar panels made?

Solar panels are constructed from monocrystalline or polycrystalline silicon solar cells that have been soldered together and sealed beneath an anti-reflective glass cover. When light strikes the solar cells, the photovoltaic effect begins and electricity is produced. The five main steps in creating a solar panel are as follows:

- Construct the solar cells

- Connect solar cells to form a panel by soldering them together.

- Attach the back sheet, front glass layer, and frame.

- Construct a junction box

- Quality assurance testing

Create the solar cells.

To make a solar panel, solder solar cells together.

Set up a back sheet, a front glass layer, and a frame.

Set up the junction box.

Quality assurance testing

Monocrystalline, polycrystalline, and thin-film panels have a photovoltaic effect.

However, silicon cells by themselves cannot power your home. They are connected to a metal casing and wiring, which allows the electrons in the solar cell to escape and provide useful power. Silicon is available in a variety of cell structures, including single cell (monocrystalline), polycrystalline, and amorphous forms, which are most commonly associated with thin film solar panels.

Manufacturing of solar panels

Solar panels that are monocrystalline are manufactured in silicon wafer formats from a single large silicon block Individual silicon wafers are cut and affixed to a solar panel during the manufacturing process. Monocrystalline silicon cells outperform polycrystalline or amorphous solar cells in terms of efficiency. Individual monocrystalline wafer production is more labor-intensive, and thus more expensive than polycrystalline cell production. Monocrystalline cells have a distinctive black appearance and are frequently associated with the sleek appearance of SunPower’s premium panels.

Solar cells that are polycrystalline are silicon cells, but instead of being formed in a large block and cut into wafers, they are created by melting together multiple silicon crystals. Many silicon molecules are melted and then re-fused to form the panel. Polycrystalline cells have a lower efficiency than monocrystalline cells but are less expensive. They have a blueish hue that is often associated with the SolarWorld aesthetic.

Finally, there are amorphous silicon cells that create flexible solar panel materials used in thin-film solar panels Non-crystalline amorphous silicon cells are attached to a substrate such as glass, plastic, or metal. As a result, thin-film solar panels, unlike standard panels, are true to their name: they are lean and bendable. Amorphous solar cells are inefficient when compared to monocrystalline or polycrystalline cells, despite being an ideal use case for versatility. First Solar is best known in the United States for producing thin-film panels.

Solar panel manufacturers complete the process by connecting the electrical systems, coating the cells with an anti-reflective coating, and housing the entire system in a metal and glass casing.

Can you construct your own solar panels?

For anyone considering installing solar on their own, there are several factors to consider, including warranties, output longevity, efficiency, and overall cost. To get a better sense of this breakdown, read our article on the benefits and drawbacks of DIY solar. Try our Solar Calculator for a personalized estimate of what a solar installation would cost based on your specific location and roof type. Check out the Illumac Solar Marketplace if you want to get quotes from local, pre-screened installers.